3.2X2.8mm SMD LED WITH CERAMIC SUBSTRATE �

� SPEC NO: DSAI6844 REV NO: V.7 DATE: APR/13/2011 �

� PAGE: 7 OF 10 �

� APPROVED: WYNEC CHECKED: Allen Liu DRAWN: J.Yu ERP:1212000022 �

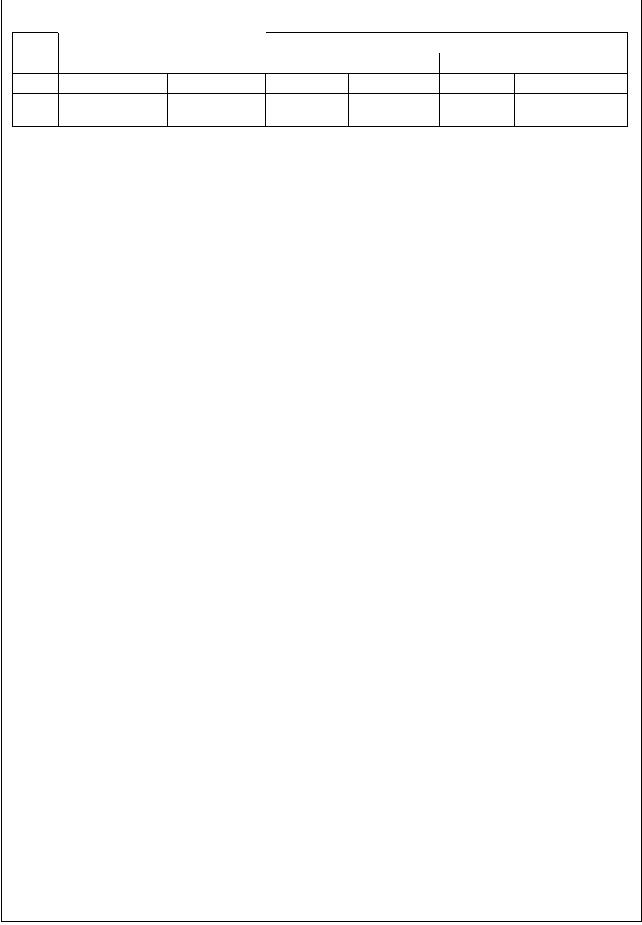

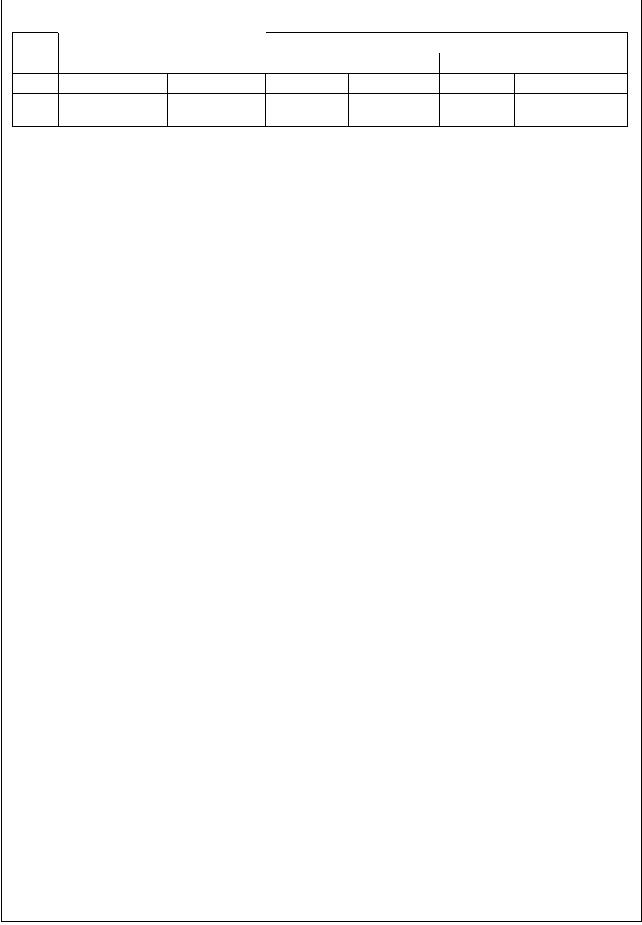

� JEDEC Moisture Sensitivity: �

� Level �

� Floor Life �

� Soak Requirements �

� Standard �

� Accelerated Equivalent�

� Time�

� Conditions�

� Time (hours)�

� Conditions�

� Time (hours)�

� Conditions�

� 2a �

� 4 weeks �

� ≤ 30 °C / 60% RH�

� 6962�

� + 5 / - 0 �

� 30 °C / 60% RH �

� 120 �

� + 1 / - 0 �

� 60 °C / 60% RH �

� Notes: �

� 1. CAUTION - The ‘‘accelerated equivalent’’ soak requirements shall not be used until correlation of damage response, including electrical, after �

� soak and reflow is established with the ‘‘standard’’ soak �

� requirements or if the known activation energy for diffusion is 0.4 - 0.48 eV. Accelerated �

� soak times may vary due to material properties, e.g., mold compound, encapsulant, etc. JEDEC document JESD22-A120 provides �

� a method for �

� determining the diffusion coefficient. �

� 2. The standard soak time includes a default value of 24 hours for semiconductor manufacturer’s exposure time (MET) between bake and bag and �

� includes the maximum time allowed out�

� of the bag at the distributor’s facility. �

� If the actual MET is less than 24 hou�

� rs the soak time may be reduced. For soak conditions of 30 °C/60% RH the soak time is reduced by one hour �

� For each hour the MET is less than 24 hours. For soak condi�

� tions of 60 °C/60% RH, the soak time is reduced by one hour for each five hours the �

� MET is less than 24 hours. �

� If the actual MET is greater than 24 hours the soak time must �

� be increased. If soak conditions�

� are 30 °C/60% RH, the soak t�

� ime is increased one �

� Hour for each hour that t�

� he actual MET exceeds 24 hours. If soak conditions are 60 °C/60% RH, the soak time is increased one hour for each five �

� Hours that the actual MET exceeds 24 hours. �

� 3. Supplier may extend the soak times at their own risk. �

� ESD Protection During Production�

� Electric static discharge can result �

� when static-sensitive products come in contact with the operator or other conductors. �

� The following procedures may decrease the possibility of ESD damage: �

� 1.Minimize friction between the product and surroundings to avoid static buildup. �

� 2.All production machinery and test instruments must be electrically grounded. �

� 3.Operators must wear anti-static bracelets. �

� 4.Wear anti-static suit when entering work areas with conductive machinery. �

� 5.Set up ESD protection areas using grounded metal plating for component handling. �

� 6.All workstations that handle IC and ESD-sensitive components must maintain an electrostatic potential of 150V or less. �

� 7.Maintain a humidity level of 50% or higher in production areas. �

� 8.Use anti-static packaging for transport and storage. �

� 9.All anti-static equipment and procedures should be periodically inspected and evaluated for proper functionality. �

� Heat Generation: �

� 1.Thermal design of the end product is of paramount importance. Please consider the heat generation of the LED when making �

� the system design. The coefficient of temperature increase per�

� input electric power is affected by the thermal resistance of�

� the �

� circuit board and density of LED placement on the board ,as we�

� ll as other components. It is necessary to avoid intense heat �

� generation and operate within the maximu�

� m ratings given in this specification. �

� 2.Please determine the operating current with consideration of the ambient temperature local to the LED and refer to the plot �

� of Permissible Forward current vs. Ambient temperature �

� on CHARACTERISTICS in this specification. Please also take meas �

� ures to remove heat from the area near the LED to�

� improve the operational characteristics on the LED. �

� 3.The equation ①�

� indicates correlation between T�

� j�

� and T�

� a ,and the equation ②�

� indicates correlation between T�

� j�

� and T�

� s�

� T�

� j = Ta�

� + R�

� thj-a *W ……… ①�

� Tj = T�

� s + Rthj-s�

� *W ……… �

� ②�

� Tj = dice junction temperature: °C �

� T�

� a�

� = ambient temperature:°C �

� T�

� s�

� = solder point temperature:°C �

� R�

� thj-a�

� = heat resistance from dice junction tem�

� perature to ambient temperature : °C/ W �

� R�

� thj-s�

� = heat resistance from dice junction tem�

� perature to Ts measuring point : °C/ W �

� W = inputting power (IFx VF) : W�

�  �

�

�  �

� �  �

�

�  �

� �  �

�

� �  �

�

� �  �

�

�  �

� 发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

AT3228SY9ZS-RV

LED 598NM YELLOW 3.2X2.8MM SMD

AT3228ZG10ZS-RV

LED 520NM GREEN 3.2X2.8MM SMD

BA56-11EWA

DISPLAY 627NM RED 3DIG 0.56" TH

BA56-11GWA

DISPLAY 565NM GRN 3DIG 0.56" TH

BA56-11SRWA

DISPLAY 660NM RED 3DIG 0.56" TH

BA56-11YWA

DISPLAY 590NM YLW 3DIG 0.56" TH

BA56-12EWA

DISPLAY 627NM RED 3DIG 0.56" TH

BA56-12GWA

DISPLAY 565NM GRN 3DIG 0.56" TH

相关代理商/技术参数

AT3228SY9ZS-RV

功能描述:大功率LED - 单色 1W Yellow 591nm Water Clear 14 lm RoHS:否 制造商:Cree, Inc. 照明颜色:Blue 波长:465 nm 光强度: 光通量/辐射通量:500 mW 正向电流:350 mA 正向电压:3.1 V 安装风格:SMD/SMT 功率额定值: 系列:XB-D 封装:Reel

AT3228ZG10ZS-RV

功能描述:大功率LED - 单色 1W Green 530nm Water Clear 50 lm RoHS:否 制造商:Cree, Inc. 照明颜色:Blue 波长:465 nm 光强度: 光通量/辐射通量:500 mW 正向电流:350 mA 正向电压:3.1 V 安装风格:SMD/SMT 功率额定值: 系列:XB-D 封装:Reel

AT-3237-TF-LW140-R

功能描述:扬声器与变频器 3700Hz 98dBA 12Vpp

RoHS:否 制造商:PUI Audio 产品:Speakers 类型:Electromagnetic 频率:900 Hz to 12 kHz 声压级:88 dBA 阻抗:8 Ohms 功率额定值:1.2 W 形状:Round 端接类型:Solder Pad 直径:15 mm 长度: 宽度: 深度:4.4 mm 磁体材料:Neodymium Iron Boran (NdFeB) 圆锥体材料:Mylar

AT32-38/42-4

制造商:Block USA Inc. 功能描述:3 phase autotransformer,380-400V 2kVA

AT32-44/46-4

制造商:Block 功能描述:3 phase autotransformer,440-400V 2kVA

AT32-48/50-4

制造商:Block 功能描述:3 phase autotransformer,480-400V 2kVA

AT325-20/21-4

制造商:Block 功能描述:3 phase autotransformer,200-400V 25kVA

AT325-22/23-4

制造商:Block USA Inc. 功能描述:3 phase autotransformer,220-400V 25kVA